Polyurethane

We manufacture a wide array of high wear resistant polyurethane components such as polyurethane decks / screens, conveyor scrapers, polyurethane skirting and screen capping.

We can produce a wide range of mounting options to suit the application like:

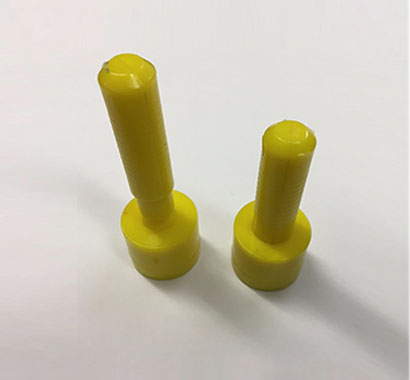

- Pin mounting - 3 types including replacement B-30 pins for STAINHAUS

- Strip mounting - 5 types including replacement strips for ISENMAN

- Screen deck body mounting - 7 different types

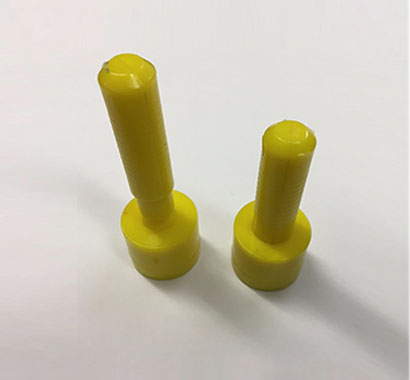

UsRubber are producing the pin / clips that are required to mount the screen deck.

For more information contact us at info@usrubber.org

The polyurethane flip flow screens are designed both for clamping connections and bolting connections to fit all kinds of screen decks.

For more information contact us at info@usrubber.org

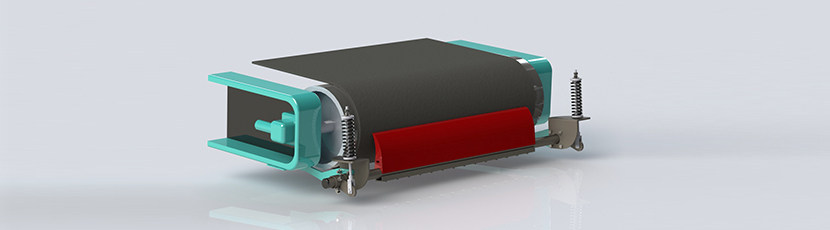

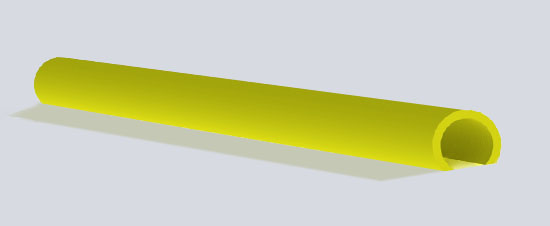

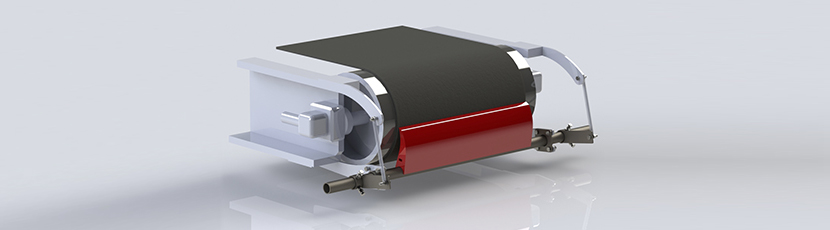

The polyurethane Tear Drop Scraper comes in a range of different sizes from 650mm up to 1200mm belt width. The polyurethane scraper sections are made of an excellent wear resistance material. We can offer two types of assemblies to choose from:

The Tear Drop Assemblies are segmented with an easy method to replace the Tear Drop Scraper Section. The sections of the scraper are 150mm long which allows the user to change certain section that could be under more contact than other sections.

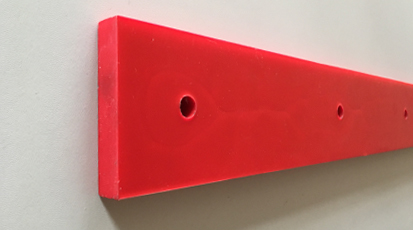

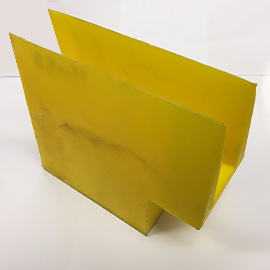

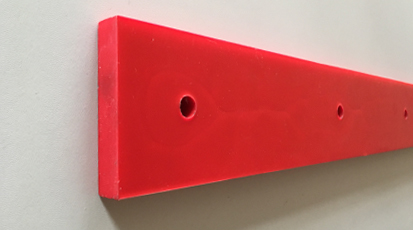

We manufacture Polyurethane Straight Scrapers to the customers' requirements. These scrapers have high durability for wear resistance. Below are two examples of straight scrapers.

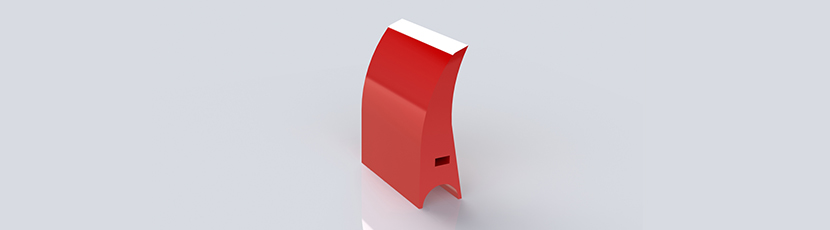

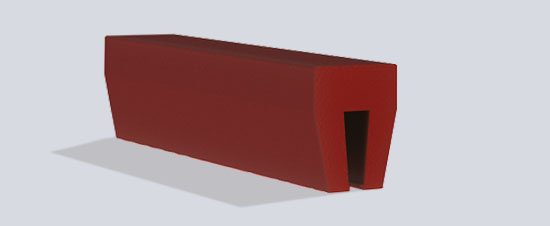

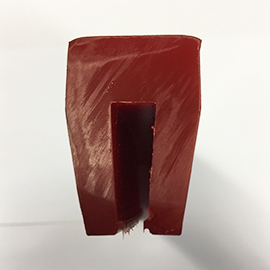

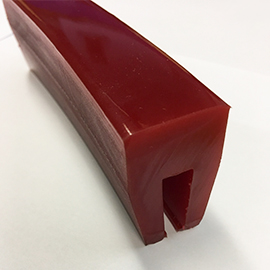

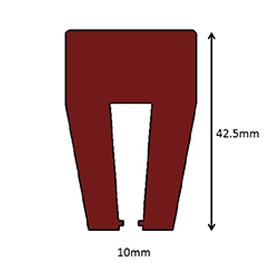

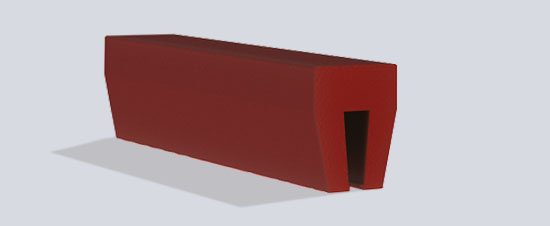

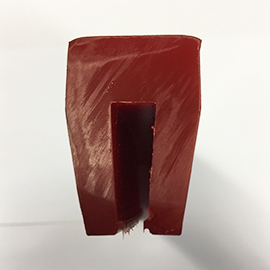

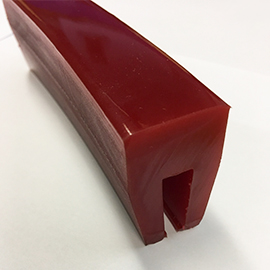

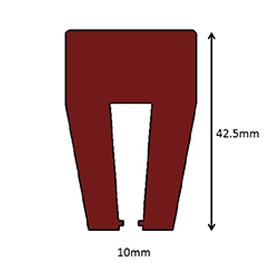

Polyurethane Capping has excellent wear and impact resistance compared to the Capping Rubber. Our Polyurethane Capping is made from high grade polyurethane compound, with the following specification.

For more information contact us at info@usrubber.org

For more information contact us at info@usrubber.org

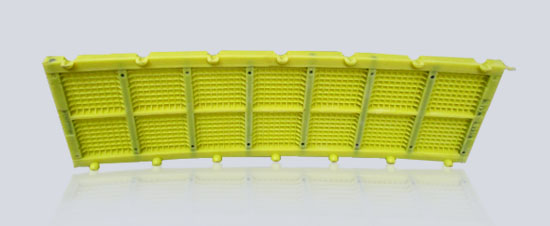

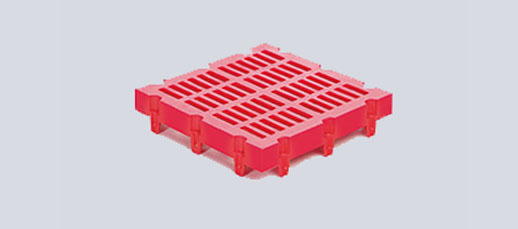

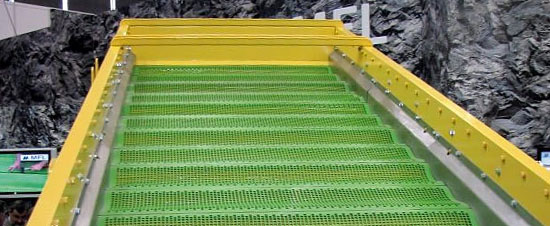

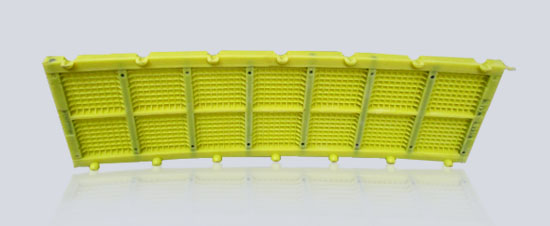

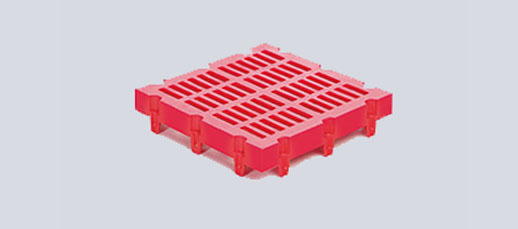

We use polyurethane elastomer material to make all of our screens decks. This material has high durability for wear and tear. It helps to reduce noise levels, corrosion proof and is self cleaning.

We can produce a wide range of mounting options to suit the application like:

- Pin mounting - 3 types including replacement B-30 pins for STAINHAUS

- Strip mounting - 5 types including replacement strips for ISENMAN

- Screen deck body mounting - 7 different types

UsRubber are producing the pin / clips that are required to mount the screen deck.

For more information contact us at info@usrubber.org

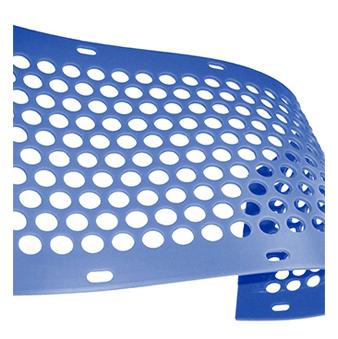

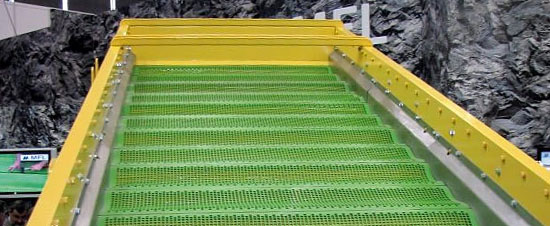

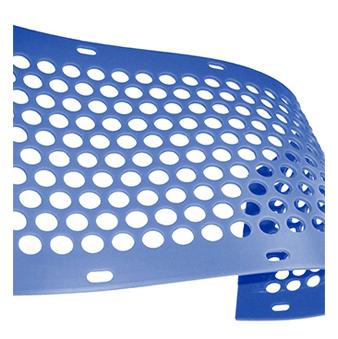

We can produce polyurethane flip flow screen. They can have various hole types, such as square holes linear pattern,square hole staggered pattern, round hole staggered pattern, slot hole linear pattern or slot hole staggered pattern.

The polyurethane flip flow screens are designed both for clamping connections and bolting connections to fit all kinds of screen decks.For more information contact us at info@usrubber.org

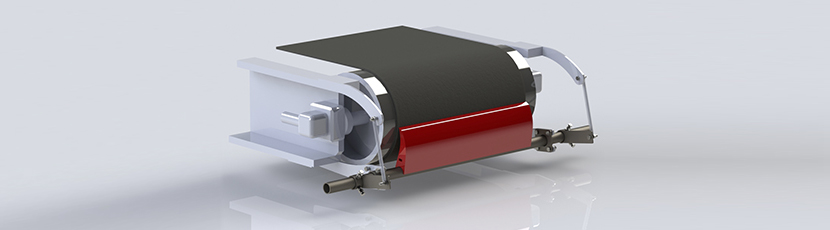

The polyurethane Tear Drop Scraper comes in a range of different sizes from 650mm up to 1200mm belt width. The polyurethane scraper sections are made of an excellent wear resistance material. We can offer two types of assemblies to choose from:

The Tear Drop Assemblies are segmented with an easy method to replace the Tear Drop Scraper Section. The sections of the scraper are 150mm long which allows the user to change certain section that could be under more contact than other sections.

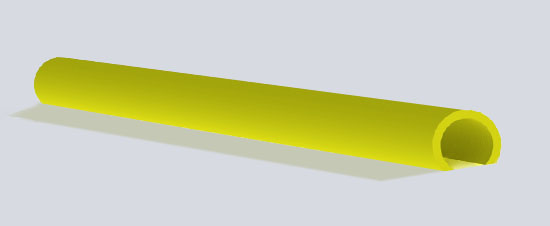

We manufacture Polyurethane Straight Scrapers to the customers' requirements. These scrapers have high durability for wear resistance. Below are two examples of straight scrapers.

Polyurethane Capping has excellent wear and impact resistance compared to the Capping Rubber. Our Polyurethane Capping is made from high grade polyurethane compound, with the following specification.

For more information contact us at info@usrubber.org

We manufactures polyurethane parts to customers' requirements.We stock a wide range of products for the screening, crushing and agricultural industries. Using dimensional drawings or examples of existing parts we can create the parts that the customer requires.

For more information contact us at info@usrubber.org